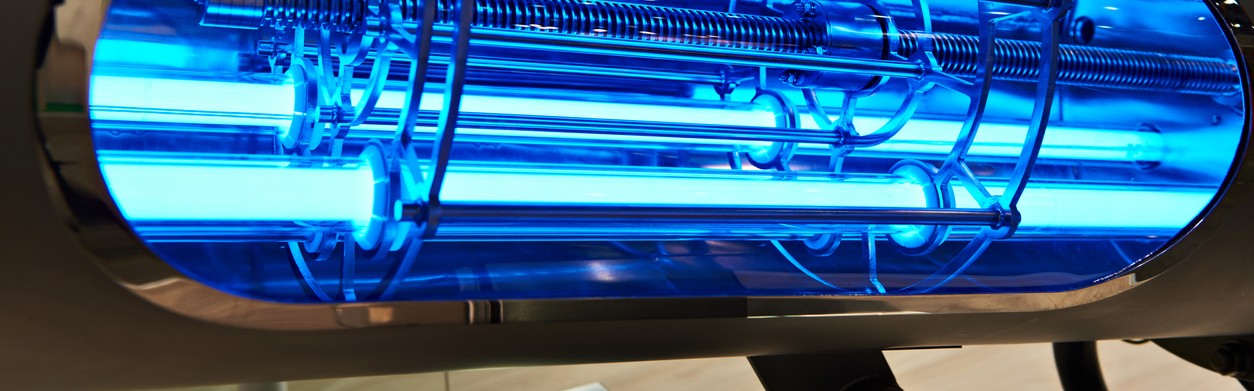

Filtration, Clarification & Ultra-Filtration (UF) Systems

Ultra-filtration or UF is a pressure-driven membrane separation process that helps removes particulate matter from aqueous solutions such as water. It provides a physical barrier to suspended solids, bacteria, most viruses, endotoxins and other pathogens to produce water with high purity and low silt density.

These systems serve as pre-treatment for many applications such as surface water, seawater, brackish water and biologically treated effluent. It is often used as feed stream into Reverse Osmosis and other membrane systems, depending on required water quality.

UF membranes typically have pore sizes in the range of 0.01 to 0.10 μm and efficiently remove bacteria and most viruses, colloids and silt. The smaller the nominal pore size, the higher the removal efficiency.

Integra typically utilise DOW UF membranes, made from high-grade polymeric PVDF material to form a hollow fibre membrane that is very durable and less prone to breakage. The hollow fibre has a dense layer or skin on both the inside and outside surfaces, forming a double-walled structure that contributes to its strength. In addition, its fouling resistance is improved by making the membrane surface more hydrophilic than the underlying PVDF polymer. With uniform pore size and outside-in flow, the DOW UF membrane creates a barrier without sacrificing performance.

FEATURES & BENEFITS

- Speciality in skid mounted membrane plants

- Vast water feed pre-treatment experience

- Key personnel with risk management approach

- Custom built solutions constructed here in Australia; for Australian conditions

- Plants built with redundancy and expandability in mind

- Service background allows our packages to be designed with maintenance and service costs considered for the long term.

- 24 hr remote monitoring control systems

- A dedicated and specialised pre-treatment team that has some of Australia’s most comprehensive knowledge and experience

- Compliant QA & Management systems

- Low fouling with high recovery

- Large membrane area = small footprint

- PVDF membrane is the strongest

- Outside-in flow membrane configuration aids cleaning

- Chemical enhanced backwash extending run time between chemical cleans (CIP)

- Dead-end or concentrate bleed capabilities

- Simple, modular design

- Requires minimal operator supervision

- PLC or microprocessor control

- Cost effective operation

For more information contact an Integra specialist today.