TwinOxide trialed as an effective biofilm remover at a popular vineyard

At Integra, our specialists continually strive to deliver customised solutions for specific industry requirements.

We conducted a trial to assess the benefits of using our specialist chemical preparation TwinOxide as a biofilm remover within a large-scale vineyard.

In order to do this, a small trial setup was created. This setup was built to inject a specific amount of chlorine dioxide via a field valve on the irrigation system.

Integra completed the following services:

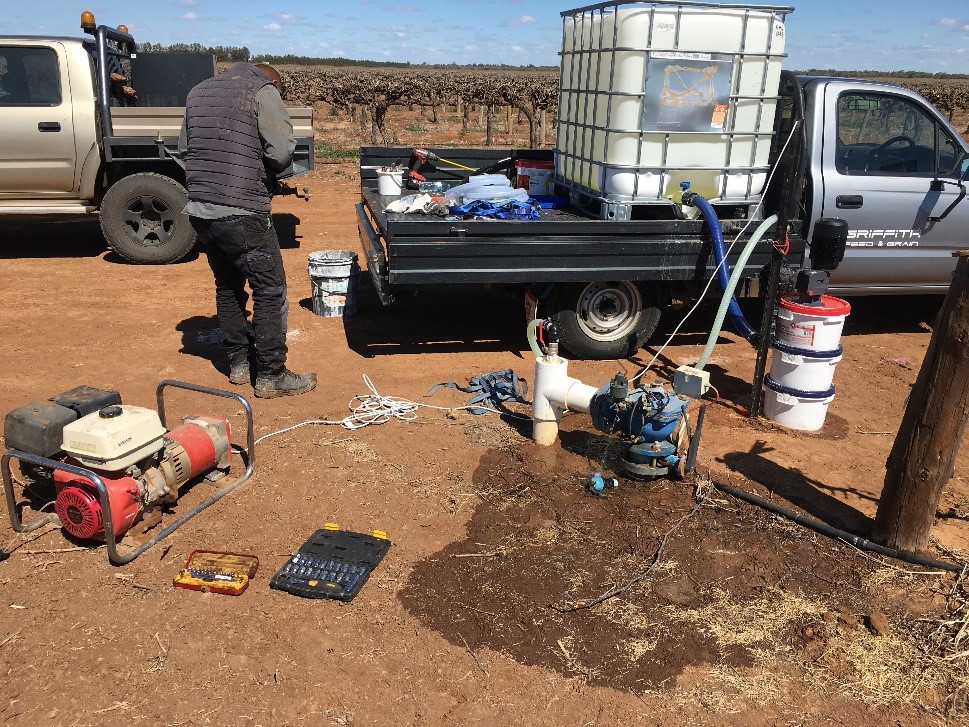

- Design and production of a portable chlorine dioxide dosing system

- Design of a chlorine dioxide line volume calculator for ease of calculations

- Carry out of the trial.

The trial consisted of injecting a small amount of chlorine dioxide solution into lines at a specific concentration. The chlorine dioxide was then allowed to sit in the lines for a prolonged period, before being flushed clean with fresh water.

The Results/ Benefits:

The results were outstanding, our client was extremely impressed with the volume of biofilm that was removed from the irrigation pipes, particularly when compared to other methods which had been trialed in the past (including high doses of chlorine).

The farmer has since decided that all dripper lines on the property will be cleaned in the same way. This solution provides a cost-friendly, highly effective biofilm removal system.

The system is portable, allowing for ease of transport between jobs and allows for the job to be carried out effectively. Integra are committed to providing the right solution for any given application.

To find out more about how Integra can help your business grow, talk to one of our specialists today.

Field Valve Inlet where chlorine dioxide was injected

Trial chlorine dioxide site. Concentrate chlorine dioxide was pumped from IBC into valve via injection pump powered by generator.

Background – Flushing pipe with chlorine dioxide.

Foreground – Flushed pipe with chlorine dioxide.